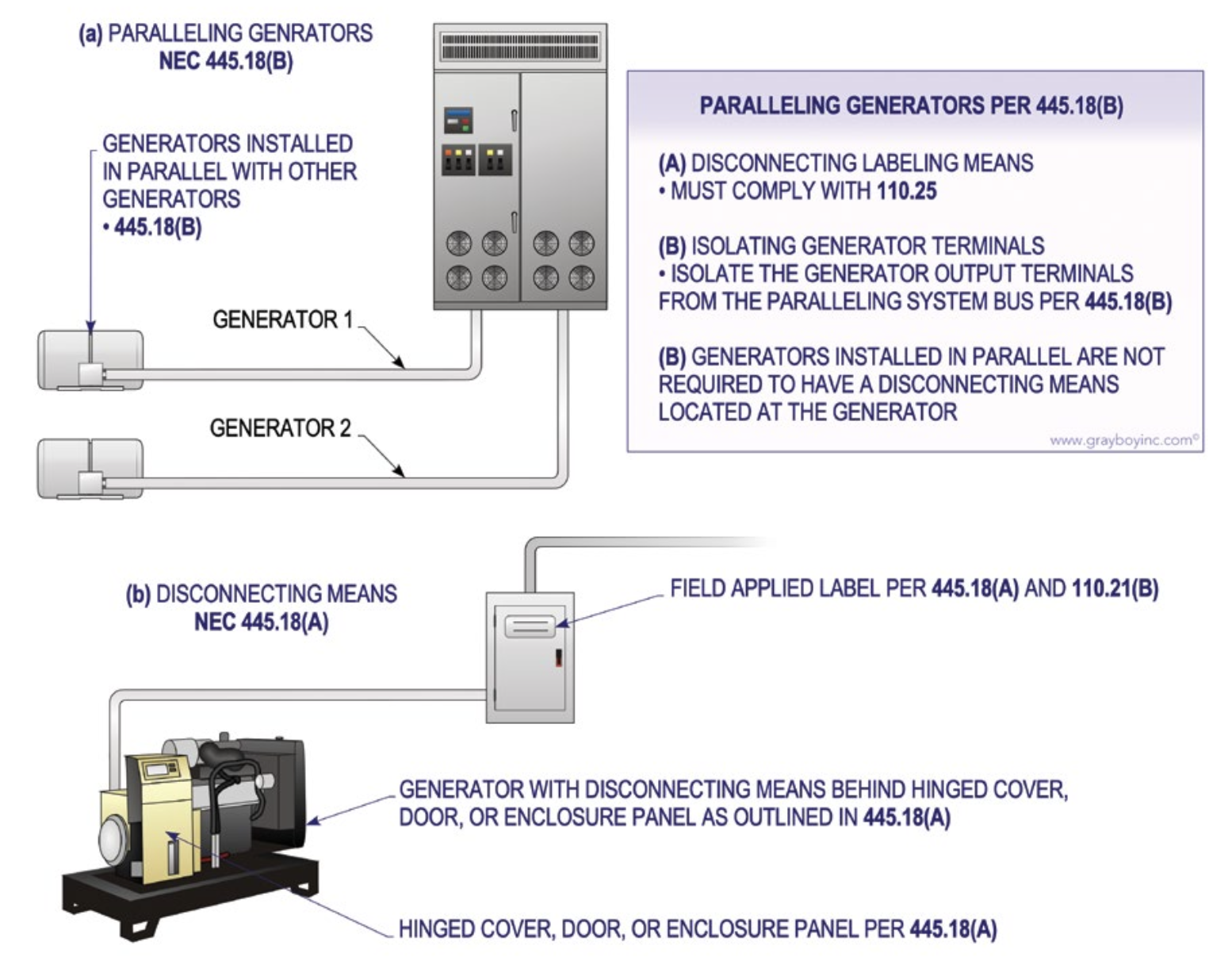

445.18(A)(B) Generator Disconnect – Parallel Installations and Location

Change Summary

-

Revision clarifies the separation of an emergency shutdown and a disconnecting means.

| NEC®Text |

|---|

|

Article 445 – Generators Material taken from the National Electric Code. is reprinted with permission from NFPA 70., 2023 edition. National Electrical Code®, Copyright 2022, National Fire Protection Association, Quincy, MA. All rights reserved. |

Expert Analysis

Modifications are made to clarify the permitted locations for emergency shutdown devices and marking. Section 445.18(B) is revised from “paralleling equipment” to “paralleling system bus” to clarify the intent of the requirement.

Leviton Solution

Powerswitch® curve top safety disconnect switches with Inform™ technology provides local and remote monitoring

|

|